Browsing through my local antiques shop, I found a Hamilton 910 from 1922.

It didn’t work, and the balance only moved at a very limited angle when I shook the movement. After taking it apart, cleaning and oiling it, the watch now ticks nicely.

It didn’t work, and the balance only moved at a very limited angle when I shook the movement. After taking it apart, cleaning and oiling it, the watch now ticks nicely.

After having let down the main spring, I removed the transmission wheel and the barrel wheel. The two case screws are also removed.

As the next step, I remove the hands and dial. I am with de Carle here - I use a hand removal tool for the hour and minute hand, but remove the second hand by carefully lifting the dial with the second hand still in place.

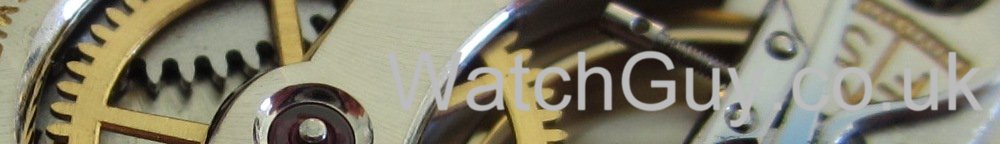

The third & fourth wheel bridge is removed and you can clearly see the centre, third, fourth and escapement wheel.

I remove the wheels and can now take out the balance cock with balance and spring. All looks in good order and complete.

The watch is now disassembled and the parts are on my bench. At the top left, you can see the gears for adjusting the watch hands. Now it's time for cleaning. I put all the parts bar the dial and the pallet fork into a cleaning solution and let them soak for a while. The jewels are cleaned out with a sharpened piece of pegwood. I also carefully scrape the surface of the pallet jewels with pegwood.

Now it's time to re-assemble the watch again. I slightly oil the jewels and put the escapement wheel, third, fourth and center wheel back into place. Before I try to place the bridge on top, I make sure that all the wheels are properly placed on top of the jewels.

I slightly oil the jewels in the bridge and very carefully place the bridge on top of the wheels and check that all the wheels are properly seated. I gently press the bridge down and make sure that the wheels turn freely.

The crown and castle wheels are slightly greased and put back, and then the winding bridge is put back into place.

Now it's time for the pallet fork to go back in. I carefully place the pallet fork and the pallet cock into the case. I make sure that everything is in proper position before I tighten the screws.

The balance wheel and the balance cock go back into place - having lightly oiled the top and bottom jewel.

Pingback: Teardown: Raketa Pocket Watch

How do you dry your pasrts? Also why was the hairspring not carefully removed from the cock so you can mark the staff and remove the hairspring to clean the hairspring in one-dip then rince it and dry, and replaced on the staff carefully replacing it just as it was .It is one step that is over looked that makes the watch porfome at it’s best. and can you tell me what other parts would you place grease to reduce more friction? And when you adj- operating angle of the pallets how do you adj the angle of a pallet, do you mean the pallets jewels?

Scott

I don’t quite know where to start …

In my opinion, the danger of damaging the hairspring in the process that you describe (as far as I can make out what you are trying to say, I guess English is not your first language) is far greater than any benefit you might get. And I’m not sure what benefit you would get.

I can’t see the hairspring getting any cleaner if removed. But I can see it getting damaged.

By the way… it’s is short for “it is”.

All the best,

Christian