With a brand spanking new fourth axis unit, I’m getting closer to my goal of cutting watch wheels….

This little wheel has 72 teeth, and measures 7.1mm in diameter. The tooth shape isn’t correct, as I just used a 60 degrees thread mill, but it’s just a proof of concept to show that wheels can be made on a CNC mill.

I’m very happy with the result, and I will get on to making fly cutters to the NIHS 20-25 standard (http://watchguy.co.uk/cgi-bin/cnc?action=nihs_20_25_wheel).

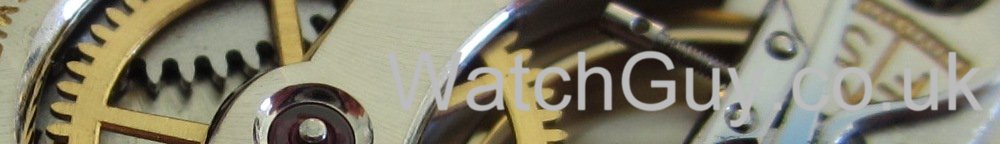

This photo shows my set-up, with the new fourth axis unit in place, and a camera to get that extra bit of precision when it comes to finding the right position for the mills.

This video shows how the spokes are cut out, using a 0.4mm end mill. The path was made using FreeCad 0.18.1.

If find the result very encouraging, and once I’m getting the hang of the fly cutters, I should be able to create whatever tooth shape is required.

A video of the wheel cutting process:

This video was taken on an earlier attempt of a slightly larger wheel with more teeth, but as you can see, I was cutting too deep (0.3mm).

A close-up of the fourth axis unit. You can get this great piece of kit on eBay: https://www.ebay.co.uk/itm/312509973014?epid=2146948572

Last but not least, a video of the parting off of the wheel:

Cever! Genius! I hope I could….

hello my friend.i got a question.do u think that it would be possible to make pinions using the same method?

Yes, you can. I have done it successfully.

When Citizen watches started up in 1930 they found it very difficuly to source machinery to make the parts for their watches so in 1936 they decided to make their own.

They started to sell machinery as a separate business in 1961 and now they make some of the finest CNC lathes on the market.

90 years from now servicing watches will be but a small part of your empire…