It’s a fine line… You can’t just polish a bridge screw until the slot looks perfect. If you take off too much material, the screw head won’t be level with the bridge any more, and you don’t want that to happen.

It’s a fine line… You can’t just polish a bridge screw until the slot looks perfect. If you take off too much material, the screw head won’t be level with the bridge any more, and you don’t want that to happen.

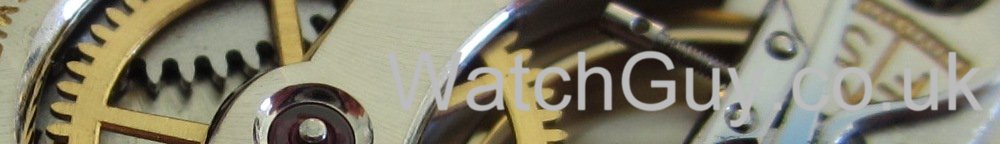

My first microscope photo shows a screw from a Movado watch bridge – as I’m just servicing the watch and it’s damaged, I thought I’d give it some love. I measure the length of the screw at 3.12 mm with a micrometer, so we can see how much material is lost in the process.

You absolutely need a screw holder for polishing, as you will otherwise generate something half-round and not very good looking. Mine was bought from Daniel in the US.

I start off with a 1200 abrasive paper.

I have thus created a level surface again. Note that I didn’t take the screw head all the way down to get rid of all the slot damage. You have to weigh material loss against finish.

Next, it’s a 2000 abrasive paper.

The next step is a 3M 9 micron lapping film with a drop of clock oil. The oil makes a huge difference to the finish!

The 9 micron lapping film with clock oil creates a better finish than anything else – forget extra-fine diamantine, polishing compound, etc. This doesn’t look perfect, but don’t forget that this is a microscope shot! You can still see some damage of the slot, but I am weighing maintaining screw length vs. perfect slot finish. You can of course decide this for yourself and take off enough material so you can re-file with a slot file, which I won’t do here, as I don’t want to widen the slot. These are all decisions that you best let the owner of the watch take, and what I do here is just my personal opinion.

Just to give you something to compare the finish to, here is a microscope shot of a Patek Philippe Calatrava bridge screw:

So now you might agree that the lapping film with clock oil actually generates quite a nice finish 😉

Now I want to check for material loss.

2.5/100 of a mm loss – that’s a great result!