The Waltham watch I took apart yesterday is next. This is a rather chunky, 20 ligne movement. All the parts are cleaned, dried and ready for reassembly.

The Waltham watch I took apart yesterday is next. This is a rather chunky, 20 ligne movement. All the parts are cleaned, dried and ready for reassembly.

I start by lightly greasing the hole for the ratchet wheel and the click.

Click spring, click and ratchet wheel mounted.

I put the wheels on the plate, and fix the pallet fork into place in the wheel bridge using some rodico. This helps putting the plate into place without the pallet fork falling out.

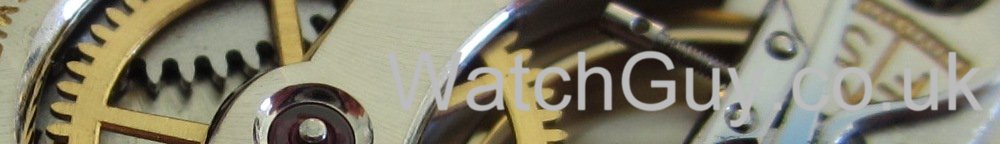

You can see the pallet fork end next to the balance bottom jewel. All the wheels are in place, and now it’s time for some oiling.

Next, the barrel and barrel bridge are put into place. I lightly grease the barrel arbor.

As soon as I drop the balance in, it starts turning. I fix the hairspring cock to the plate, and then put the balance cock in, making sure that the regulator pinches the last winding of the hairspring. The hairspring doesn’t stick together any more – on further inspection before cleaning, I noticed oil on the hairspring that had caused the sticking.

Side view of the movement with the balance fork and escapement wheel visible.

The broken hour hand. I’ve looked for a replacement, but I can’t find a nice minute and hour hand in a similar design with the right dimensions, so I will attempt to solder the hand back together.

I start off by lightly sanding the point where the hand broke off, and then applying a tiny amount of solder. I do the same with the broken off hand.

Using two small bits of rodico, I fix the two parts of the hand onto a sheet of paper. Both parts have a tiny bit of solder applied to them, so I just have to heat the joint up to solder them together.

You can see the small brown burn on the paper next to the joint – the hand is soldered together.

With the rodico removed, here is the end result. The proof is in the pudding, though. It has to survive mounting to the hour wheel.

I push the pin that prevents the rotation of the movement in the case back out, and put some shellac in place to hold it. I’ve decided on this method rather than a firmer fix to prevent this happening again. Should someone else decide that it’s a wise choice to force the pin, it will easily give way and no further damage will be done.

As the subdial for the second hand has come loose, I clean both dials and put a piece of cardboard inside the main dial where the subdial goes. This serves to maintain an even distance so that I won’t glue in the subdial crooked.

Now I replace the subdial and glue it to the main dial using shellac. This will hopefully not flake like the original cement-like substance that was used.

My timegrapher doesn’t like the slow beat of the Waltham movement and only picks up every other beat. No problem, I’ll adjust the watch once I have the dial and hand back on.

I won’t order the crystal on its own – I will wait for some more parts I need to combine postage.

The story continues here …

Beautiful and delicate work once again, Christian. And thank you once again.

I think this is the heaviest watch (of any type) that I have ever owned, let alone held. It has a lot of silver in it, which frankly is one reason I bought it.