Leena has sent this watch from Norway in the hope of getting it working as it should.

Leena has sent this watch from Norway in the hope of getting it working as it should.

This watch looks nice with an original dial and a solid 18K case, but the oscillating weight is not turning. I’m curious to see what’s happening. The nasty punch marks on the rotor is the first clue! There is enough slack in the rotor post and rotor bush to jam the rotation.

The nasty punch marks on the rotor is the first clue! There is enough slack in the rotor post and rotor bush to jam the rotation. While removing the rotor, I noticed there are some further pointless punch marks on the plate under the rotor gib.

While removing the rotor, I noticed there are some further pointless punch marks on the plate under the rotor gib. Here is the underside of the winding mechanism.

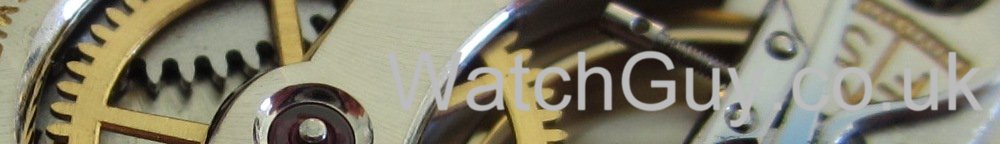

Here is the underside of the winding mechanism. The rest of the movement looks to be in really good condition.

The rest of the movement looks to be in really good condition. I have removed the balance and ratchet wheel.

I have removed the balance and ratchet wheel. Base plate with only the pallet remaining. Almost perfect condition. I wonder if the “watchmaker” that made those ugly marks on the rotor has gotten this far in servicing the movement.

Base plate with only the pallet remaining. Almost perfect condition. I wonder if the “watchmaker” that made those ugly marks on the rotor has gotten this far in servicing the movement. Setting mechanism.

Setting mechanism. As the balance staff is almost £50 a shot it is better Christian performs this operation.

As the balance staff is almost £50 a shot it is better Christian performs this operation. Here Christian is removing the old staff with a Platax tool.

Here Christian is removing the old staff with a Platax tool. Here Christian is riveting the new balance in the staking sett.

Here Christian is riveting the new balance in the staking sett. All the parts cleaned and ready to put back together.

All the parts cleaned and ready to put back together. Here you can se the complete gear train back in place.

Here you can se the complete gear train back in place. Barrel and train Bridge back in place.

Barrel and train Bridge back in place. Balance and winding mechanism back in place.

Balance and winding mechanism back in place. Great performance with a new balance staff.

Great performance with a new balance staff. We suspect that the earlier watchmaker thought a cal 550 rotor bush would fit. But this movement uses a cal 470 rotor bush and stem that are smaller. So to make the bush fit he has broached the rotor to make the larger 550 bush fit. Of course the bush is now too large for the stem so he has tried to punch the hole smaller. We have sourced the correct cal 470 rotor bush and stem. But now the hole in the rotor is broached too much. To fix the problem, Christian solders the original cal 470 rotor bush in place.

We suspect that the earlier watchmaker thought a cal 550 rotor bush would fit. But this movement uses a cal 470 rotor bush and stem that are smaller. So to make the bush fit he has broached the rotor to make the larger 550 bush fit. Of course the bush is now too large for the stem so he has tried to punch the hole smaller. We have sourced the correct cal 470 rotor bush and stem. But now the hole in the rotor is broached too much. To fix the problem, Christian solders the original cal 470 rotor bush in place. Christian has performed magic with an almost perfect soldering.

Christian has performed magic with an almost perfect soldering. Movement back in the case. The oscillating weight is once again swinging as freely as the day it left the factory.

Movement back in the case. The oscillating weight is once again swinging as freely as the day it left the factory. A nice classic that deserved being fixed!

A nice classic that deserved being fixed!

Hi, I services thin calibre and I have a problem. The manual winding is very rough. Is There a special way to oil the mainspring or other parts?

Tank you

Martin

Nothing unusual. You have to check individually if all parts of the winding mechanism run freely.

Very entertaining blog post Christian. I can do a basic service, but I do not possess your machining skills. I’m still learning to use a staking set.

Just a question, I noticed that you have the lift angle set to 52 degrees, but I thought this caliber series had a 49 degree angle? Is it not important to set it with your machine, or maybe it was selected after the photo was taken? Or maybe that’s not the lift angle…

What was wrong with the balance staff?

Top pivot was broken.

Wonderful! I love the pics and steps showing how the watches are fixed. The first time I discovered this website, I spent a couple of hours reading the blog.

Wow…what amazing work on such a small piece. Well done to Christian for that. I suppose the variance was not such that soldering the bushing off-centre or vertical was much of an issue. Also well done to Mitka for resurrecting a timeless classic.

That’s absolutely right. There was only a very small gap between the rotor and the rotor bush, so that I could solder it in centred and straight.

I also supported the rotor with rodico that it was absolutely level with the new bush.

According to some internet sources, the first rotors of this kind were made with bushes that were meant to be replaced, while later the complete rotors and axles were seen as replacement parts. Since these are hard to get today, I wonder whether there is a fix for this problem. After all, it should concern at least many thousands of valuable watches. Can the later rotors be rebushed? Is it possible to reconstruct the axles? Might it be an option to insert a hull made of softer metal that can take the wear? Or are proper maintenance and timely sourcing of original parts the only ways to go?

Thank you very much!