IWC made the calibre 854B movement starting around 1970.

IWC made the calibre 854B movement starting around 1970.

This movement was used for the famous “Ingenieur” series.

This model is a 9k gold version, with gold batons on the dial.

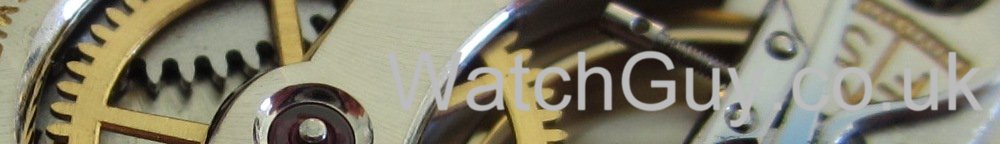

A first look at the 854B movement. You can already see the two fine adjustment screws – the innermost one for the beat error, and the outermost one for the beat rate.

The amplitude is still pretty good, but I’m not sure about the lift angle of this movement. Yes, I know, you can determine it ….

With the rotor removed, you can see the IWC typical auto winder construction. The two discs that touch the rotor excenter move the auto winder arm left and right, and the long and short ratchet arms turn the intermediate winding wheel alternatingly. Note that the rotor post shape allows for shock absorption. The balance also has Inca shock protection, so this watch was made for a bit of rough and tumble.

The case clamps have two screws each, and again, this shows that reliability was high on the agenda.

The dial has gold batons.

A first look at the bottom plate with the dial removed. At 9 o’clock, the “Probus Scafusia” IWC logo. The dial washer is missing, but that can easily be replaced.

The top side with the rotor removed.

A detail photo of the intermediate winding wheel with the auto winder arm.

I’ve removed the upper balance jewel in this photo, and you can clearly see the two fine adjustments.

The pallet fork is removed, and you can see the nice escape wheel cock.

The centre second pinion with its upper bush plate. Note the little spring in the wheel bridge that applies light pressure to the side of the pinion to prevent the second hand from stuttering.

The gear train is now visible, and you can also see the hacking feature, which is operated by the tip of the winding stem.  The mainspring can surely do with a bit of cleaning.

The mainspring can surely do with a bit of cleaning.

Now I turn my attention to the bottom plate.

The setting mechanism has two intermediate wheels.

All the parts are clean, and I can start putting the movement back together. I get asked a lot why I don’t remove the balance cock… I have previously removed it, and taken both jewels out, but I put it back in for cleaning. This protects the balance staff and hairspring during cleaning, whilst still giving full access to the cleaning fluid.

The barrel bridge is in, and I put the gear train in place.

The keyless works are put into place.

Beat error and beat rate adjusted, and we have a very nicely performing watch with good positional variation.

The second hand pinion is in place, and I can now put the auto winder on.

The auto winder bridge holds the intermediate winding wheel and auto winder arm.

The rotor is jewelled, which is nice.

The bottom plate is ready for the dial.

And ticking again. This is a very nice watch, with a great movement – something that you can wear every day without worrying. There is also a date version (calibre 8541B) which would be my choice as I can never remember the date 😉

I was lucky enough to be given a 1968 Yacht Club with a blue dial from my father last year. It’s a Cal 8541B, which is regarded by many as the best automatic movement ever made by IWC and needless to say I think it’s a beautiful watch.

It’s good to see Christian was able to service this watch, because I’ve heard that IWC do not make parts available to independent watchmakers.

Christian, thank you very much for the fine work on my watch, and for the fascinating walk through here.

A perfect walkthrough for Cal 85x owners. But I am, as always, puzzled by the B suffix. Both of my Cal 8541 have the double adjustment of beat rate and error. There was at one time an explanation on the IWC forum but it is no longer available.

I’ve edited the post, and taken out the comment about the “B” having to fine-adjustment regulators, as you so rightly pointed out that the 8541 had it as well.

Lovely, IWC movements always seem to be well engineered and nicely finished.

Why is the dial washer so often missing on movements Christian? Is it because it’s not a critical part so less thorough watchmakers than yourself leave it out or don’t bother to replace if they lose it?

I’m a bit baffled by that as well… it’s a fairly vital part, as the hour wheel will ride up, and hour and minute hand will get out of sync if it’s missing.

It’s like the punch marks that lots of watches have under the balance cock – somebody didn’t quite know what they were doing.

That’s a lovely watch, congrats to the owner and nice post Christian 🙂

I was scratching my head somewhat with the auto winder, until (I think) it clicked – is there an eccentric disc or cam fitted to the movement side of the oscillating weight that drives the arm mechanism via the follower wheels?

That’s the only way I can mentally picture the power transmission…

Thanks, Ben

Yes, that’s exactly how it works.