Richard sent in this JLC for a service. The dial and hands are in great nick, and so is the case.

Richard sent in this JLC for a service. The dial and hands are in great nick, and so is the case.

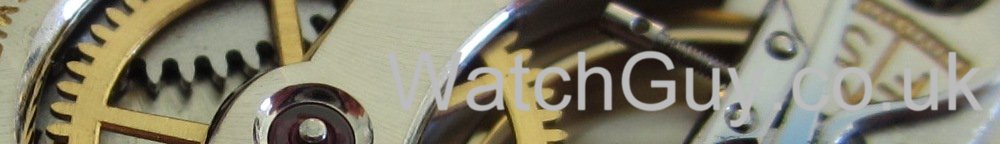

Now it’s time for a look inside …

A plastic case ring, probably from a cheap quartz watch. Not something you want to find inside a JLC 🙂

The movement needs a service, too.

To make a “fitting” case ring, I start off with an aluminium blank off eBay.

I turn the inside until the movement fits snugly.

Then I turn my chuck around, and turn the outside of the ring to fit the case.

A good start – the ring fits into the case and the movement into the ring.

Now we need two holes for case screws. Every time I use these drills, I have to think “TUNGSTEN CARBIDE DRILLS??“

With a tap, I put the threads in.

Testing the fit with case clamps.

Now I can start on the movement.

A T-end mainspring, which I will replace.

The case has a very strange pendant tube, which isn’t really a tube. No chance to fit a proper waterproof crown over that, so I take it out.

I find a new pendant tube that fits, and order a new crown for it.

The movement parts are clean, and I can start putting it back together.

The balance jewels go in first.

And we have a beating movement.

Now I can put the bottom plate together. Look at the “39” scratched into the plate. This sort of stuff always gets me. What vital information was that so that it had to be scratched on the plate? IQ of the guy who did it? There is perlage decoration, and you have to take a needle to it…

And we have a decent performance.

The new case ring, new pendant tube and new crown.

Nice looking outside and inside. The crown is generic, but looks quite nice on the case.

The crown is generic, but looks quite nice on the case.

Hello

Great job.

The watch case is not the original?

What case is compatible with the k800 movement?

Where to get it?

Thanks

Greetings

No chance of finding an original case.

Love reading this tear down. Very educational, even for me as a hobbiest. As you service a lot of JLCs could you give me a tip? I’m having trouble with the t-shaped bridle of the main spring. What is the trick getting it into the slot of the barrel? Do I just put it in the barrel, place the cover with bridle sticking out of one of two holes in the cover and give it a good wind? Does it need to slip into the groove per se?Thanks a million!

Start putting the mainspring in as usual by hand. Once you have one to 1 1/2 turns in the barrel, turn the whole mainspring until the T clicks into its slot in the barrel. Then put the rest of the mainspring in.

To put the lid on, make sure the slot fits right over the T.

WOW..amazing work.

This is brilliant work. Super beautiful watch, too. I have a hand-wound Longines from the 60’s that looks nearly identical, but I almost like this one better. Again, I loved reading everything and especially the non-ordinary work that went into ‘righting the situation’ going on here.

would it be rude to ask what the price was for the job Christian?

The total with parts came to about £175 if I remember correctly.

very reasonable considering the case ring machining/fabrication

Fantastic work that went into this!

That’s a lovely dial – simpler is better 😉

Did you have to mill or drill the channel for the winding stem, or was that part of the blank?

That pendant tube looks to me like something designed to wear so that the case doesn’t?

I filed that with an oval file. I don’t think the pendant tube that was in there belongs to the case…

wow, great machining skill on the case ring Christian. great job.

Always interesting to se some tinkereing beyond a regular service. Nice work!

just in case some of those who are viewing this post might take it for granted- his turning of a new case ring is a sadly uncommon skill amongst most watch repairmen these days. i call them watch repairmen not really as an insult, but as an attempt at accuracy. that Christian can fabricate parts as they are needed is an important skill that is all to often lacking. it is the difference between a watchmaker and watch repairman.

A lovely watch, and a good job! Funnily enough, my dad has just machined a similar movement/case ring for me today for an Omega I’ve got in for a service.

We’ve used acetal (plastic), have you ever considered using it? It comes in all sorts of bar and sheet sizes, and is even easier to work than aluminium, but still dense/hard enough to be useful for these sort of applications.

Got to try that – just ordered myself a bit of Acetal on eBay. Thanks for the hint!

Acetal is probably more suitable for case rings that don’t have case screws in them, e.g. where you don’t have to make a thread in the case ring…

Why ‘decent’ performance? because of the beat error? 326 degrees I would say it beats that! Nevermind the straight line….

Also great work on the rest of the case!

Christian, I can’t thank you enough. The watch is now finally finished and I am made up. You have yet again done a truly magnificent job.

Many, many thanks

Richard