Another one of Torsten’s watches – a great looking Junghans Chronograph. The dial and case look super-cool. A very clean design, with no frills. Just how I like watches 😉

Another one of Torsten’s watches – a great looking Junghans Chronograph. The dial and case look super-cool. A very clean design, with no frills. Just how I like watches 😉

Note that the crown is on the left, and the pushers on the right.

The movement works, but the second hand of the chronograph gets stuck on the minute hand, and the amplitude isn’t too good, and there is a bit of a beat error. When winding, the watch makes a pretty terrible noise…

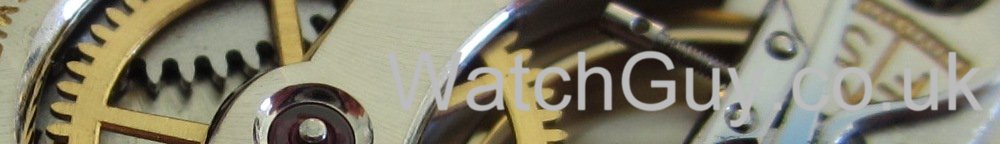

Great looking movement – the Buren 11, used by Junghans for their Chronograph and re-named 688.13.

The minute dial of the chronograph has some damage that won’t come off with a brush, but it’s not too bad.

Bottom plate with a simple, but effective date change mechanism.

The centre wheel isn’t in the centre, and you can see it at 1 o’clock of the barrel.

Great movement, with a very technical look. No fancy decorations, but everything well made.

I take photos of every part with its screws as I take it off the plate, which makes reassembly a lot easier.

Almost done with the chronograph plate.

Next layer down – the movement itself. Now you can see that this is an automatic watch, with the famous Buren microrotor.

The wheel train.

There is an odd brass washer above the winding pinion, and I don’t think it should be there. This does not bode well …

And this is the reason for the washer. Some of the teeth of the winding pinion have worn off a bit, and that caused the terrible sound when winding. Doesn’t look like the washer did much good.

As with most chronographs, no lack of parts to clean.

I can’t get hold of a new 1.60 x 0.105 x 380 x 10.5 mainspring, but the old one doesn’t look too bad, so I will reuse it. I start off with braking grease on the barrel wall.

Next, I put the balance jewels back together.

With the barrel on the plate, I start off with the wheel train.

With the balance in and the mainspring half wound, I adjust the beat error and beat rate. Looking good!

Then, the auto-winder and micro rotor go back on.

With the movement layer done, it’s time for the chronograph.

Now that the chronograph is back together, I adjust the depthing of the gears.

Now I will put together the bottom plate.

Dial and hands on, the movement goes back into its case.

Great looking chronometer!

Why do you keep showing me all these photographs of lovely watches I don’t own??

Did you source a replacement for the winding pinion?

I’m afraid I couldn’t find a new winding pinion for love nor money. As it’s an automatic, it’s still usable without a new one…

Cant say I have any problem with my Seiko Auto, and that is designed to only wind via the rotor!

I have been reading up recently on 3D printing technology and wonder how long it will be until such machines are in every workshop routinely re-producing worn parts like that pinion.

Already you can buy desktop sized printers like the uPrint for about £10k… it’s a brave new world 😉

Still trying to get the right winding pinion… fingers crossed.

I’ve actually been in contact with a guy that does 3D printing, but they can’t print parts thin enough for watches that are sturdy and have a decent surface. At the moment, 3D printing only works for larger stuff I’m afraid. As soon as the day comes that they can print small enough, I’ll be the first one with a printer in his workshop!