Those who know me are aware that I’m normally not a great fan of quartz watches. The reason for that isn’t that I’m technophobic – I love the technology behind quartz watches. I just can’t stand the cheap plastic finishes found on most quartz movements.

Those who know me are aware that I’m normally not a great fan of quartz watches. The reason for that isn’t that I’m technophobic – I love the technology behind quartz watches. I just can’t stand the cheap plastic finishes found on most quartz movements.

The good news is that there are exceptions, and the Omega calibre 1471 is one. This is a stunningly beautiful quartz movement, made with all the care that a watch movement deserves!

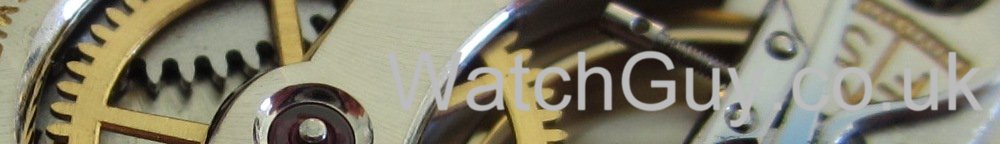

And here it is in all its glory. Fully jewelled with 13 jewels, decorated plates, and the minimum amount of plastic necessary. Now that’s a quartz movement I like!

And here it is in all its glory. Fully jewelled with 13 jewels, decorated plates, and the minimum amount of plastic necessary. Now that’s a quartz movement I like!

The back of the dial and the bottom plate with 6 jewels.

The circuit with the quartz crystal, and the coil.

The gear train in its full glory. I do pretty much all the work on this movement under the microscope.

The parts are split into those that can go in the cleaning machine and those that can’t. As the rotor is magnetic, it won’t go into the cleaning machine, as it just attracts all he metal particles that are in the cleaning fluid.

Most bits just go into the basket for small parts.

Back from the cleaning machine.

I begin the reassembly under the microscope. The gear train takes me a while, as the rotor is magnetic and wants to go anywhere but where it belongs.

The movement is back together. What a beauty!

The bottom plate is no less beautiful.

Back in the case with a new battery. Onto the tester, and I’m done.

Onto the tester, and I’m done.

Hi Christian just found your blog on the omega 1471 great work.I am trying to fix my

wife’s omega 1471 as the negative battery contact is broken my questions are

how to remove crown and how much do i have take off to replace contact.

Thanks for any help kind regards john

PS are you on SCWF by any chance

The setting lever has a little indentation on the opposite side to the winding stem. Pressing down into the indentation releases the winding stem.

I’m afraid I don’t do watch forums, as I cherish my psychological health 😉

Christian, The view you showed of the assembled gear train is correct, and the manufacturer’s data sheet is misleading. I tried fitting the setting wheel the other way up but it is not possible, as the top pivot is a larger diameter than the lower jewel hole.

Thank you for replying and your assistance with the time setting problem with my watch. It would appear to lie with a worn clutch wheel.

Your view of all the wheels exposed shows the setting wheel with the gear pinion that engages with the minute wheel downwards. The exploded view of the mechanism from the manufacturers appears to show it upwards which would throw the wheel of the setting wheel below the minute wheel. This would affect meshing with the clutch wheel.

As I am experiencing problems getting setting to work at all is the way you have shown it definitely correct?

This post is almost 4 years old – I would presume that they way I show the wheels is correct, as the watch worked afterwards 😉

I get the watch to work except in setting the hands. Can I send you an attachment which shows the exploded view of the movement please?

I think I need an email address to send the data sheets I obtained from Cousins as a pdf.

No problem downloading the data sheets ourselves … Maybe this is a job for a watchmaker?

Thanks Christian. Cal 1471 is not listed by Cousins. The basic movement appears to be ETA 282.001. I thought you might be interested in a look at the exploded view, however I could not have assembled the gear train without the aid of your blog. Many thanks.

I note from your photo of the train wheels all in place that the rotor is central in in its lower bearing. I am finding it leaping upwards and sticking to the stator, preventing placing on the top plate.

Did you have this problem and managed to get round it?

William,

Try to put a small screw across the bottom pivot of the rotor – that will make it stick in it’s bush and prevent it jumping up.

Many thanks Christian. I am sure that will do the trick.

Hi,

I have got as far as all the train in place bar the intermediate wheel and the rotor. I had thought the intermediate wheel would hold down the rotor which steadfastly insists on rising from its bearing and sticking to the side of the stator. The rotor just floats upwards whatever I do. Did you have some cunning plan to restrain it in place?

I am going to try a piece of brass shim secured over the top of the rotor with a split in it to enable me to pull it out once the top plate is engaged in all the wheels.

Hi. Very interesting to see the working part of this watch. I recently inherited a similar watch and I have two questions, maybe you can help me. First, where would be a good place to purchase a replacement dial face? The watch currently has a champagne dial. Second, are the gold links in this watch solid gold, or “plated”? I would appreciate any information.

Thank you very much.

Mario

I have to agree,

an extremely good movement indeed, not a lover of quartz movements myself but that one would surly be an exception to the rule.

lucky owner to have such a nice watch, congratulations.

That is a very nicely executed movement and a very nice watch generally!

What prompted the service?

The battery was empty, and, when I checked the watch, the power consumption was too high and the jewels were dry and dirty.