Kent has sent this nice looking Omega in for a service, but not everything is as nice as it seems.

Kent has sent this nice looking Omega in for a service, but not everything is as nice as it seems.

First impression and the movement looks to be in decent shape.

First impression and the movement looks to be in decent shape. The performance is very bad and something is not as it should be.

The performance is very bad and something is not as it should be. The dial screws are a mess.

The dial screws are a mess.  After some effort I manage to tickle out both improvised dial screws.

After some effort I manage to tickle out both improvised dial screws. Looking at the movement from the side, the balance is wobbling like mad and when I take it out of the movement I notice that the balance staff has been glued into place.

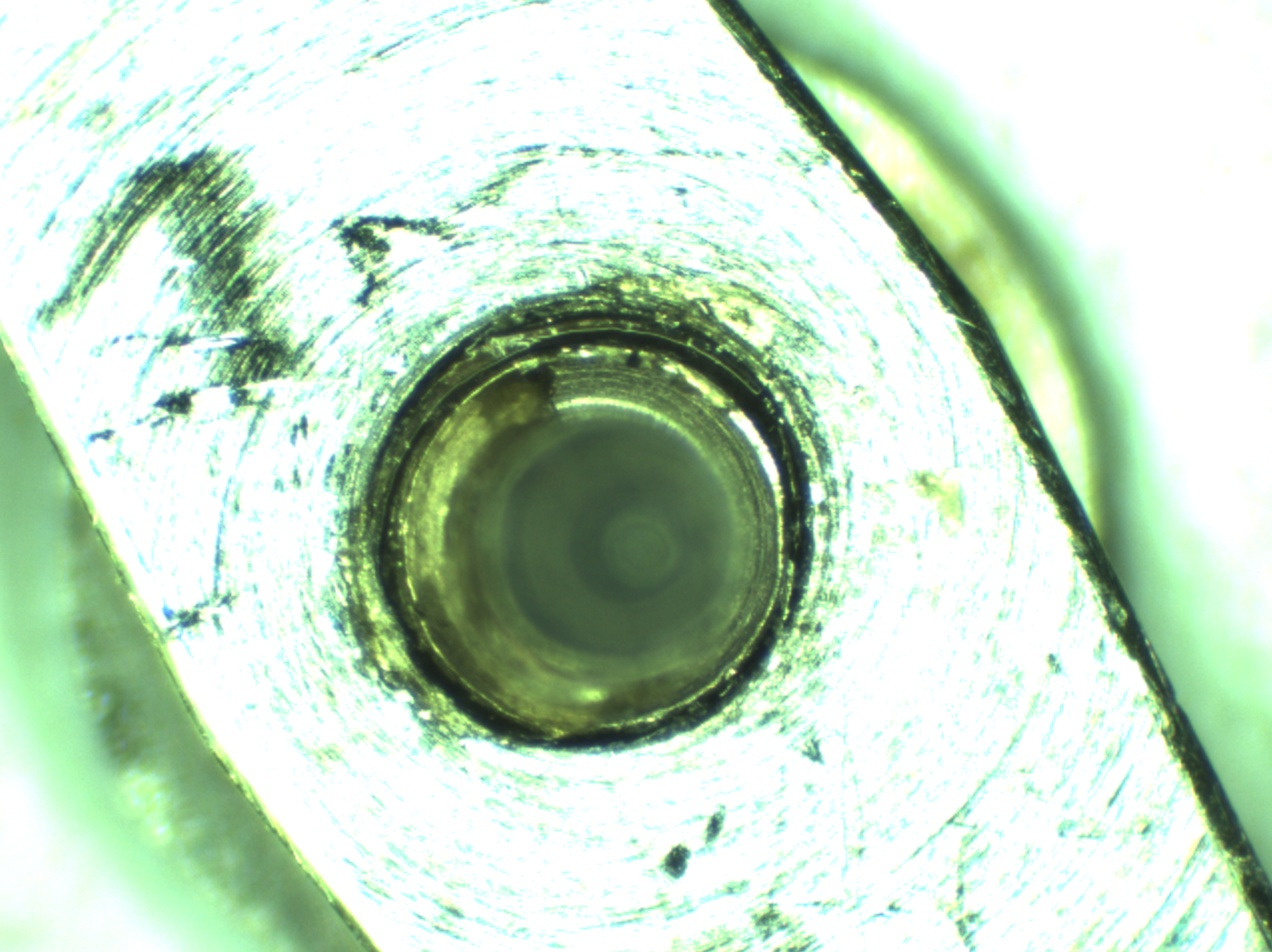

Looking at the movement from the side, the balance is wobbling like mad and when I take it out of the movement I notice that the balance staff has been glued into place. Under the microscope you can see that the balance hole for the staff is oval from an unsuccessful attempt of replacing it. There is no way we can rivet a new staff in place.

Under the microscope you can see that the balance hole for the staff is oval from an unsuccessful attempt of replacing it. There is no way we can rivet a new staff in place. I’m lucky and find donor balance for the watch. It’s missing the hairspring, but I have the hairspring from the old balance.

I’m lucky and find donor balance for the watch. It’s missing the hairspring, but I have the hairspring from the old balance. I see that the new balance fits before taking the movement apart and cleaning it.

I see that the new balance fits before taking the movement apart and cleaning it. The Omega non-shock protected balance cock taken apart for cleaning. I like the disk that secures the cap jewel and regulator in place

The Omega non-shock protected balance cock taken apart for cleaning. I like the disk that secures the cap jewel and regulator in place Taking the watch apart you can see that someone has used a lot of oil as the movement is basically swimming in it.

Taking the watch apart you can see that someone has used a lot of oil as the movement is basically swimming in it. The collet did not fit the new balance so I suspect the hairspring might have come from another watch. But as I have no other hairspring I opt for tightening the collet to make it fit the new balance. When I now test the watch, it is loosing 1000+seconds a day. I replace 4 balance screws with smaller ones that are about half the size of the old screws and I get close to around 0 seconds a day. The balance is now completely out of poise and the movement looses and gains a lot of time depending on positional variation.

The collet did not fit the new balance so I suspect the hairspring might have come from another watch. But as I have no other hairspring I opt for tightening the collet to make it fit the new balance. When I now test the watch, it is loosing 1000+seconds a day. I replace 4 balance screws with smaller ones that are about half the size of the old screws and I get close to around 0 seconds a day. The balance is now completely out of poise and the movement looses and gains a lot of time depending on positional variation. Here you can see the balance on a poising tool. I see where the heaviest point is on the balance.

Here you can see the balance on a poising tool. I see where the heaviest point is on the balance.

You can see that the watch is out of poise when the balance stops at the same spot over and over. You can tell where the heaviest point on the balance is as it will be facing downwards.

To fix this, one must remove the balance screw and remove tiny amounts of material before putting the screw back in place. When the balance starts to stop at random points you know your balance is poised. To poise the balance you have to remove the hairspring, but leave the roller in place. Here you can see the movement back together and ticking.

Here you can see the movement back together and ticking. There final test is to see how the watch is doing in different positions. Dial Down

There final test is to see how the watch is doing in different positions. Dial Down Dial Up

Dial Up Crown down

Crown down Crown up

Crown up Crown right

Crown right Crown left. As you can see there is still some variation, but I think this is acceptable. I have mixed feelings about posing as it is very fun to make a balance more accurate, but there is always the risk of one of the tiny balance screws breaking and rendering the balance wheel useless.

Crown left. As you can see there is still some variation, but I think this is acceptable. I have mixed feelings about posing as it is very fun to make a balance more accurate, but there is always the risk of one of the tiny balance screws breaking and rendering the balance wheel useless. This is a shot from a Junghans calibre 59 where generations of people have been tinkering on the balance screws and even filing into the balance wheel itself.

This is a shot from a Junghans calibre 59 where generations of people have been tinkering on the balance screws and even filing into the balance wheel itself. Here is another shot of an IWC calibre 82 balance wheel, where a screw has been broken off and someone added solder to compensate.

Here is another shot of an IWC calibre 82 balance wheel, where a screw has been broken off and someone added solder to compensate.  Back over to the Omega. The setting mechanism is back in place and the movement is ready for the dial and hands.

Back over to the Omega. The setting mechanism is back in place and the movement is ready for the dial and hands. I have fitted the correct Omega dial screws.

I have fitted the correct Omega dial screws. Dial and hands back on the watch looking good.

Dial and hands back on the watch looking good. I now put the movement back in the case.

I now put the movement back in the case. Now that is a nice looking vintage Omega.

Now that is a nice looking vintage Omega.

Olá. Você disse que para corrigir a falta de equilíbrio do balanço e preciso retirar o parafuso do balanço e remover pequena quantidade de material, e possível remover esse material do parafuso sem retirar ele do balanço? E se não e possível, pode explicar porque? Obrigado

My Portugese is non-existent. Could you please try English?

Thank you so much for your videos. I learn more each time I watch you work and explain what you’re doing.

CHEERS,

Kenny

I never cease to be amazed at the beautiful photographs and clear descriptions you always take the time and effort to do. It’s always an absolute joy to read these pages. Thank you.

Would this be one of those jobs where you didn’t end up making any money? 😉

Lovely movement – a redial? seems v good condition.

Hello! If I may ask, how long did it take for you to fix the balance?

Thank you,

Bogdan

P

P.S. GREAT JOB!

Wow, another quality watch recovered from disaster. You never know what can of worms you are going to open. Nice to see the art of timing and poising still survives.

Incidentally, I was once told by an old watchmaker in the jewellers where I worked in the1970’s, that when Omega started to use monometal screwless balances they issued a service bulletin stating that poising was a thing of the past but if necessary lead paint could be added to the rim. Not sure if this is correct or just an old pro messing with the trainee?

Anyway nice work Mitaka.

Nice job! Especially working on the balance wheel and hairspring is a fiddly job. I’m sure that kind of bodge jobs aren’t done by watchmakers. Probably a case of “I know a guy who can fix it CHEAP”. Original parts are rare and are getting rarer everyday. With the vintage market nowadays these kinds of “repairs” are done to be able to sell the watch in running condition. Please don’t ask how it’s running though.

Very nicely resurrected!

I can never understand how such dreadful work on such a fine machine is done by people calling themselves “watchmaker”.