This watch was sent to me by Constantine of Rochester, NY, for a service. He told me that the dial was quite damaged, so I expected a watch in not too good a shape.

This watch was sent to me by Constantine of Rochester, NY, for a service. He told me that the dial was quite damaged, so I expected a watch in not too good a shape.

The dial looks as though someone has smeared over it with a dirty finger, only missing the bits around the hour marks because the finger couldn’t get in there.

Only one way to find out what happened to the watch ….

Looks like fire damage to me - the brass is almost red, and some of the stainless steel has been blued. No gasket. My guess is that this watch was heated over 130° C. That also explains the way the dial looks. Below the 6480, the back is stamped "III 57", which points to a manufacturing date in the third quarter of 1957

With all that temperature damage, the watch still ticks. The balance amplitude is ok, the lines are a bit shaky, but all in all, not too bad considering what must have happened to this watch

Looks like the hottest point was around 11 o'clock. The areas around the hour markers are less damaged as the markers themselves take away and diffuse some of the heat

No reason not to treat the dial as carefully as I can - I wrap it in watch paper and put it to the side

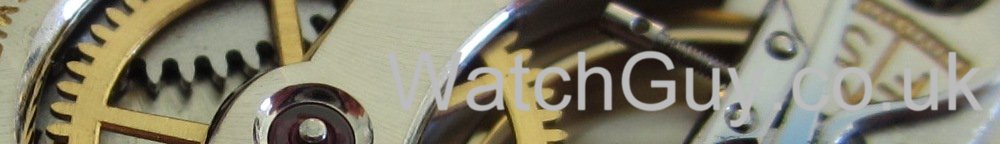

I start off with the bottom plate which shows less damage as it was protected by the dial and has less components that stand out

Now I turn the movement around and start by taking off the balance cock with the balance - balance colour almost red from the temperature damage

On first sight, this looks bad. But, looking at the discolouration, the watch probably didn’t get far over 150°C, so with a bit of luck, there won’t be any deformation of parts.

I will put the parts into a strong ammonium-based cleaner, which should return the brass parts back to their normal colour. I’m also getting a quote for a dial restoration.

Now I have to order some gaskets and a new main spring. When the parts have arrived, I will put the watch back together again.

After a bit of Dialux Vert and a buffing wheel, the wheel bridge looks a lot better. Still a tiny bit yellowy, but there is not much I can do about that

The barrel bridge and the second hand assembly fitted - looks a lot better than with the discolouration we had before

That’s enough for today – and it’s the weekend!

I will resume next week as the dial will take a good 12 days until it’s done. Can’t wait to see what that will look like!

Wednesday, February 29th 2012

Today, I want to complete the top plate of the movement. I start by cleaning the pallet fork with some pegwood. I don't put it in the cleaning fluid, as that can dissolve the shellac that holds the pallets

I put the pallet fork into place and put the pallet cock in. I lightly oil the pallets and the pallet jewels

As the timegrapher is showing a beat error of 3.2ms, I will have to adjust that first before making any rate adjustments.

Adjusting the beat error is very fiddly - you have to insert an oiler from the side to block the collet and then move the balance. This takes me 8 attempts to get it right

March 15th, 2012

The dial came back today – and David Bill & Sons have done an amazing job. The dial looks great and original – well done!

As the watch is getting a new crystal, I'm giving the case a quick polish. This won't get rid of any deeper scratches, but it will make the watch look a lot nicer

The bezel gets a quick shine as well - but the deep scratches stay. If you want to get rid of those, you have to start with 240 grain sand paper and work your way up to Dialux Vert

Well, I’m very pleased indeed with the end result – if you compare the last photo to the first, this watch has brushed up rather well!

Well, I’m very pleased indeed with the end result – if you compare the last photo to the first, this watch has brushed up rather well!

Dear Christian,

I had been very fortunate to be given a Rolex 6424 , albeit not working last year. I had been a watch hobbyist repair guy for 4 years now, dubbling with ETA , Japanese , Chinese movements.

I bought a few parts new ( mainspring , second Axis train wheel ) to reoair the rolex. I had never owned a Rolex and longed to wear one on my 69 years old wrist. Alas, the spring balance was damaged during my repair . I looked for half a year and found anothe 1210 spring balance in HK. I bought it , but again I was without luck or probably not the right skill to fix the balance assembly to the bridge..

I more or less gave up. Is it possible that I send the Bridge and the balance wheel to you . And you find a replacement hair spring ( will be great if you have a 1210 ) . In both these possibilities , what is your best advice and what is the cost ?

Hi Loh,

Please use our booking form at https://watchguy.co.uk/cgi-bin/book and we can take it from there. I will need all the movement parts, and all the broken hairsprings / balances /etc. to try to make a working movement out of that.

Kind regards,

Christian

Hi, Christian,

Thank you for showing your wonderful restoration work. I own a Oysterdate Precision 6694 dated in 1960 (on the inside of case back). Similar to this example, on the bottom plate the serial number is stamped with “N” and 5 digits of numbers. I checked several online sources of info for serial number lookup but never found something like this. Do you happen to know the reason? Thank you for any info.

Regards,

Jessy

Hi Jessy,

I’m afraid I don’t. I’m sure someone on a watch forum will know.

Best regards,

Christian

Just brilliant you know your story

The brassy color of the plates is not due to heat but damage from overly harsh cleaning solution or being left too long in the solution.

I love to see something resurrected in this fashion 😉

I am so much enjoying this website with your stories and detailed photos. Great craftsmanship and very educational for someone like me, a watchlover with no technical skills.

The end result is phenomenal. Just phenomenal. The before and after photos, and everything in between, tell the story very well. I can’t wait to see the watch in person. Thanks so much for doing a great job.

Pingback: Service and dial restoration: Rolex 6480

Pingback: 1958 Rado Automatic 21 Jewels AS1361N

Looking forward to the re-assembly story!

It’s always so much simpler to tear a watch apart — than to put it back together again, isn’t it!

While you’re waiting for the new parts to arrive, you better take care no one sneezes on that cloth with the approximately 40 itty bitty parts, because poof, they’ll all disappear into thin air, never to be seen again :).

All safely tucked up in a plastic container now 😉

I just put them on watch paper after taking them out of the alcohol rinse and blowing them dry so that any left-over alcohol can evaporate.

Thank you so much Christian! I sent you an e-mail. You are doing an amazing job disassembling and diagnosing my poor pitiful watch. Frankly, I’m amazed it was working as well as it was before.

Pingback: Teardown Rolex 6480 with temperature damage