We have a new addition to our workshop – a 60W Fiber Laser!

We bought it mainly to cut parts more accurately and faster than with our CNC milling machine, but as a side effect, we can now also engrave.

We are using LightBurn instead of EZCad as our software of choice, as it offers more settings and allows for the correction of the thickness of the laser beam when cutting parts.

It took a bit to get the first parts cut successfully, as there are a fair amount of setting to get right. The speed of the laser, the frequency, the power, … so we started off with quite a few deep fried parts before getting anything useful out of the machine.

After 3 days of tinkering around, we finally managed to get decent parts cut out …

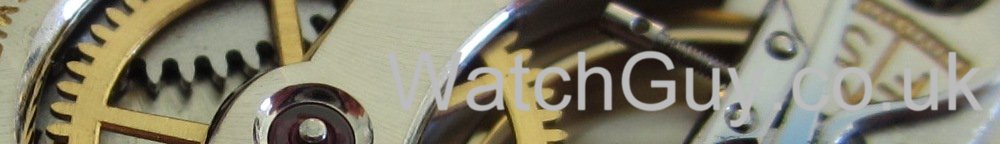

This is a small selection of our trial pieces, amongst them a JLC 497 hook spring, a Rolex 3135 setting lever spring, an Omega 563 date corrector, and a Smiths setting lever spring.

So far, so good!

Now to the topic – service marks. We never offered to put those into your case back, as they usually look fairly ugly, and don’t give enough information. Now we got a shiny new laser, we can put some meaningful service marks in your case back, and we will offer that as part of our service from now on (if you opt in). It’s an option you can tick on our booking form.

This is what the mark looks like – it offers you our company name, the job number, and the month and year the service was carried out. The aim is that anyone out there with Google at hand can easily find the service record for your watch. It’s 8.3mm x 2.2mm, so plenty of those will fit into a case back. The size is comparable to any hand-scratched service mark you will find.

Our smallest part so far out of the laser – a JLC 497 shock spring, here on a penny coin next to the late Queen’s nose.