We’ve had one of these before, and quite some time ago… These are quite rare, and were used in the British nuclear submarine fleet. As you can’t have luminous compound there (it would set off all sorts of radiation alarms), they have no luminous compound, but a while dial with black markings and hands, so that the watch can be read nicely in the low light conditions in a submarine.

We’ve had one of these before, and quite some time ago… These are quite rare, and were used in the British nuclear submarine fleet. As you can’t have luminous compound there (it would set off all sorts of radiation alarms), they have no luminous compound, but a while dial with black markings and hands, so that the watch can be read nicely in the low light conditions in a submarine.

The start/stop/reset pusher on this one does nothing, but the movement itself runs well.  The case back shows the usual nuclear submarine markings – the scratched out 3306 had a luminous compound dial, so these have that scratched over and punched “3312” on top of that. There are newer versions that how 3312 in the original number as well.

The case back shows the usual nuclear submarine markings – the scratched out 3306 had a luminous compound dial, so these have that scratched over and punched “3312” on top of that. There are newer versions that how 3312 in the original number as well.

The problem reveals itself straight away, as the start/stop/reset lever spring is broken. In itself not a big deal, but the problem is that you can’t get parts for this movement for love nor money.

The problem reveals itself straight away, as the start/stop/reset lever spring is broken. In itself not a big deal, but the problem is that you can’t get parts for this movement for love nor money.

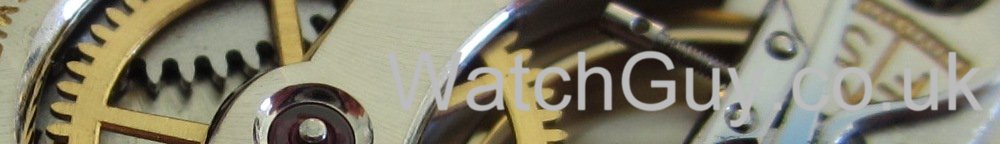

This photo shows the broken off spring – the rest isn’t even there any more, e.g. someone opened the watch and removed it. That doesn’t make it any easier to make a new spring …

This photo shows the broken off spring – the rest isn’t even there any more, e.g. someone opened the watch and removed it. That doesn’t make it any easier to make a new spring …

Luckily enough, I have a decent photo from the earlier 2220 I serviced, and I used that to produce a CAD drawing of the spring using FreeCad. This super software also produces the tool path, and if you want to make one of those yourself, you can download everything you need from watchparts.org.uk – I’ve uploaded the drawing etc. to there.

With the toolpath loaded into the machine, I mill the spring with a 0.8mm end mill out of spring steel.

Looks perfect, and works perfectly as well.

Impressive Work!

What CNC mill are you using? Looks great!

This is a £700 mill off eBay 😉

Hey Christian, thanks for this wonderful website! Could you please share the model of the mil?

That one isn’t available any more, but just search for cnc milling machines on ebay with a 24000 rpm spindle.

Thank you Christian for the fast response.

Regarding CNCs in Watchmaking, have you succeeded in cutting wheels with the desired accuracy ?

I really am trying to find a way to mil my own wheels and baseplates (goal is to make a basic handwound movement on my own).

Could you please share some resources on the setup you use and what you achieved so far (I have seen old posts in which you nearly succeeded)?

Thank you very much for your time and looking forward hearing from you 🙂

Regards,

Yavor

Hi Yavor,

I have managed to make a decent mill for cutting wheels, but your best bet might be to buy them ready made – you can get them in Switzerland.

That means that you have to cut the teeth on your fourth axis, and then cut out the centre and spokes.

Brilliant!

Just amazing stuff Christian.

excellent excellent

That is why I love coming to this blog. Not too many workshops can fix something like that! Well done!