I tend to write about the more exotic watches we service here, but the bread-and-butter watches can be interesting work as well!

I tend to write about the more exotic watches we service here, but the bread-and-butter watches can be interesting work as well!

This Rolex doesn’t keep good time, so the customer decided to send it in for a service.

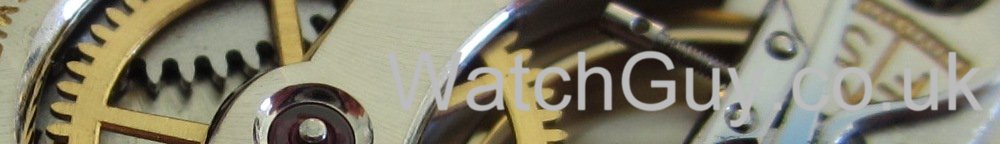

Lots of dirt, but nothing unusual on first sight. The performance isn’t anything to write home about – the movement is barely ticking.

The performance isn’t anything to write home about – the movement is barely ticking.

Also, both dial feet have broken off …

The barrel has a lot of old grease and abrasion in it. This watch hasn’t been serviced in a couple of decades at least …

The broken off dial feet.

The parts are cleaned, and I can put the movement back together.

As usual, I start off with a new mainspring.

The 3035 is a step up from the previous 1500 family, but still has a balance cock instead of a bridge. But it has a quick-set date, and the beat rate is adjusted on the balance with screws. Not a bad movement, but I would make the step up to the 3135, which I like a lot better. Not that this is a bad movement at all.

The dial side shows the snappy date change. The quick-set date wheel hasn’t been put in yet.

The movement is back together and adjusted.

The old luminous compound on the hands is brittle, and has started to break up.

Before I can solder on the dial feet, I carefully mark the old position.

Dial foot soldered on. The main point to observe is to use as little solder as possible, and to heat up very quickly. This will prevent damage to the dial.

Both feet soldered on.

No dial damage at all, and the luminous compound on the hands perfectly matches the dots on the dial. I mixed the Bergeon standard yellow with a tiny bit of orange, and a sprinkle of umbra pigment.

Ready for the case back.

That looks a lot better than before.

Movement cased, and ready for testing. The two fibres at 8 and 9 o’clock are on the outside of the new crystal, just in case you are wondering 😉

This post shows you a bit of the more mundane side of our workshop. Nevertheless, we try to do every job right, and this Rolex certainly was worth the effort.

I have a 16030 will the 3135 font in it

Pains taking work with a lovely result.!!! Its interesting to see that a few people suggest chemical adhesive for the dial feet. I thought these were to be avoided because of fumes/vapour leaking into the watch over time and damaging it.

I wouldn’t be worried about fumes if you give enough time for them to evaporate. My issue with chemical adhesives (we’ve tried quite a few) is that they don’t stick well enough. But maybe there is some magic glue out there, so please let me know if you have suggestions.

have you tried JB Weld Christian?

I have indeed, and it doesn’t hold properly. The feet break off at the slightest knock.

Hi Cristian,

Soldergun?

would you be so kind to show ue in a set of pictures how you do this including the prepartion?

thanks,

Hi Ron,

I wrote an article about this for “Timepiece”, and it’s in the current issue. If you aren’t a member, you can download the issue in three month’s time from bwcmg.org.

What’s the cost to have this watch serviced? Where can I post photos?

There is a price list on our web site. You can’t post your photos here – it’s my blog 😉

Why This Watch Matters This reference 16030 has a flawless linen-finished dial that, along with the beautifully aged and still fully intact lume dots and hands.

Very nice. Who would have thought that as well as the ‘engineering’ aspects you also have to display artistic talent – matching the tone of the lume. Nice!

Great workmanship, Christian. Than you for sharing.

The watch looks very nice again.

I didn’t find that work mundane to read about at all. Nice job.

Christian, given the inherent risks with soldering, is there no acceptable chemical alternative for refixing dial feet?

We’ve tried all sorts of glues, but to no avail. Nothing holds well enough.

JB-Weld?

We have tried all sorts of two component materials, but with no luck

Bravo! Soldering dial feet surely must be one of the more anxiety inducing services one performs in this line of work. Really exceptional work as usual. Thanks for sharing.

Not mundane at all, professional high quality work! (as always).

A very interesting dial feet repair job with very good success and i am sure very time consuming. How did you manage it so well and did you use a picticular machine to melt the solder? regards.

I use a Weller 100W soldering gun 😉 Preparation is everything …